If the result is the other way round, we are good to go; no action required. That’s because there are static documents that must be manually updated. ProjectManager is award-winning project and portfolio management software that has multiple activity planning, schedule and tracking tools to plan, manage and monitor costs in real time. The main advantage of activity-based costing is that it allows for more precise cost allocation by recognizing that different products or services may consume resources at different rates. By breaking down costs according to activities, businesses can better understand the true cost of their operations and make more informed decisions about pricing, budgeting and process improvement.

It reinforces top to bottom commitment to process and product innovation to achieve some competitive advantages. (a) Determining a price point (or range of prices) for an approximate combination of features and benefits. A large amount of mandatory cost cutting may result in finger printing in many parts of the company. It may bring savings in one part, while there may be cost reduction in some other parts.

Some companies may include robots into production which can achieve significant cost saving. For example, Tesla had included robots in its car production process. As a result, the Model 3 body line is now 95% automated, including the transfer, loading, and welding. Company ABC produces tumbler for a very competitive market, due to the similarity with many other suppliers. It is not willing to increase its selling price because it is hard to differentiate from other products in the market.

Lack of Customer Focus

Now all you have to do is get everyone inside and outside the company to adhere to this number. Although target costing emerged more than 30 years ago, yet only in 1990’s this system came into notice. Main reasons for late popularity of target costing could possibly be that target costing focuses heavily on new product development and Japanese companies which practice the system most are very secretive about their new products/activities. In Japan, target costing is has gained importance and widely practiced in more than 80% of the companies in the assembly industries and more than 60% of the companies in processing industries. It emerged in Japan in 1960s as a consequence of difficult market conditions.

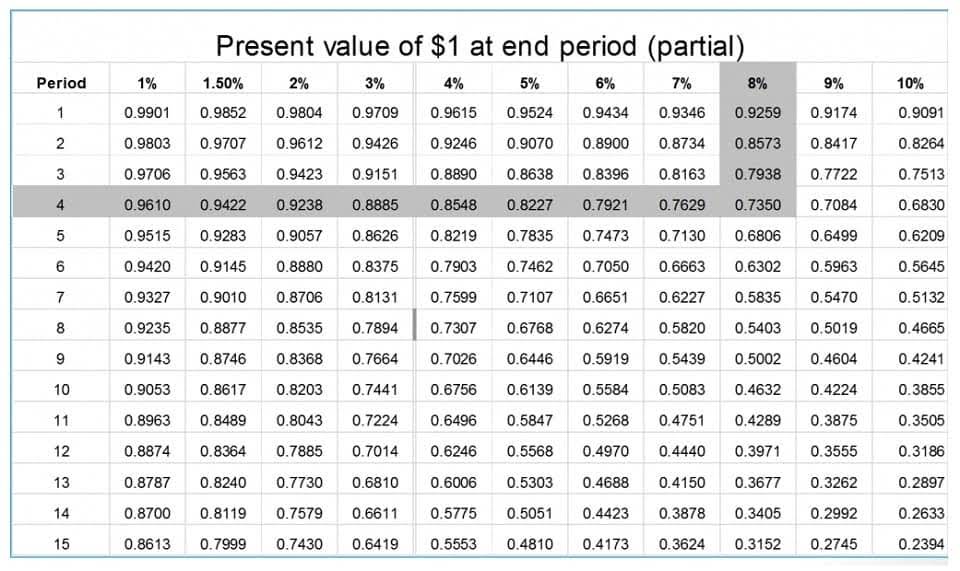

This is opposed to the much more common approach of creating a product that is based on the engineering department’s view of what the product should be like, and then struggling with costs that are too high in comparison to the market price. The market size in each category has also been mentioned in the chart by way of number of potential units that can be sold or by potential revenues. The real life examples of such goods are passenger cars, writing pens and a number of other consumer durables. Specific market share can be captured by catering to the needs of the customers identified in such cases, since the target price shall be higher, higher target cost does not matter. However, by and large, the basic product meant for a chunk of consumers will have to be sold at a lower price, thereby target costing assumes greater significance for the general market segments. Target costing is a highly structured product development discipline, which involves understanding customers’ needs, industry pricing dynamics, product complexity and life cycle analysis, and supplier relations.

Establishing Cost Targets and Design Optimization

- The cost figure obtained traditionally is implemented and if found higher, reworking of production processes takes place and costs are tried to be adjusted accordingly.

- Value engineering and manufacturing simulation tools are critical in target costing.

- In order to successfully reach this allowable cost, a great deal of effort isrequired from each department to tighten overall cost.

- As a matter of fact, the term ‘value’ has different meanings for different persons.

- In contrast, activity-based costing takes a more detailed and accurate approach by assigning costs based on specific activities that consume resources.

2) Determine the target price which customer will be prepared to pay for the product. Deduct the target profit margin from the target price to determine the target cost. It target costing and how to use it is a target price which is determined by using various sales forecasting techniques in which consideration is made for design specifications of the product and competitive market conditions. To motivate all company employees to achieve the target profit during new product development by making target costing a company wide profit management activity. In other words, Target Costing is a cost management tool for producing overall cost of product over its entire life cycle with the help of the function engineering and research and development.

- By simulating changes in raw material prices, labor rates, or production processes, teams can better understand potential cost fluctuations and prepare accordingly.

- Setting a target cost early in the development process can restrict design flexibility, making it challenging to adapt to changing market demands or customer preferences.

- When there’s a gap between your current cost and target cost, the target costing strategy will be involved finding ways to make purchasing, manufacturing, and marketing more efficient.

- Target costing is a strategic approach used during product development to ensure that a product can be made at a cost that allows for competitive pricing and desired profit margins.

- With the help of value engineering and value analysis, opportunities, for cost reduction can be identified easily.

The goal is to align production costs with market-driven prices, ensuring the company remains competitive and profitable. By considering costs early in the product development process, businesses can make informed decisions about materials, manufacturing processes, and design features to meet cost objectives without compromising quality. They continuously monitor costs throughout the development cycle, adjust designs as needed to stay within budget, and consider life cycle costing to ensure long-term profitability. By integrating strategic decision-making and value-based targeting, they ensure that products meet both technical and financial objectives, contributing significantly to the overall success of target costing initiatives. Implementing target costing in procurement involves several key steps.

What is Branch Accounting? Need, Types

For example, if a product uses 500 machine hours, and the cost driver rate is $10 per hour, the allocated cost for that product would be $5,000. This step ensures that each product or service receives a fair share of the total overhead costs. Once the cost drivers are identified, calculate the cost driver rates.

Key Steps in the Target Costing Process

As the company operate in accordance with market change (price change), it is more suitable for a competitive market. In order to use this method, total costs must be equal or less the target cost otherwise it will impact profit margin or selling price. The target costs include variable cost, fixed cost, and manufacturing overhead costs. This method is simpler and easier to implement, making it suitable for businesses with uniform production processes and minimal variability in overhead costs. However, because it applies a broad allocation method, traditional costing can sometimes lead to inaccurate cost distribution, potentially distorting product pricing and profitability. Management needs to aggressively seek customer feedback, and then products must be designed to satisfy customer demand and be sold at a price they are willing to pay.

Targetcosting adds value to the production process by eliminating non-value added activities, thus paving the way for decreased costs passed on to the consumer. Target costing enables companies to ascertain a more realistic price as well as strengthen competition among firms to offer quality products at lowercosts. A critical aspect of this definition is that it lays emphasis on the fact that target costing is much more than a management accounting technique. Consider life cycle costing to evaluate the total cost of ownership, including initial production costs, maintenance, and disposal costs.

Activity-based costing may also be used for allocation of indirect costs which is more rational than traditional costing system. With the help of value engineering and value analysis, opportunities, for cost reduction can be identified easily. Value engineering involves searching the opportunities to modify the design for reducing the cost without reducing the quality of the product. These case studies highlight the strategic benefits of target costing across various industries, demonstrating its potential to enhance competitiveness, profitability, and customer satisfaction. Failing to adequately understand customer needs can derail target costing efforts.

If target cost cannot be attained, then efforts are made to reduce the cost by redesigning and simplifying the product and by changing the methods of production. It is a technique, on the basis of which cost reduction and profit planning can be made. Target costing is a cost management technique which is very much helpful to any organisation in an increasingly competitive situation. It is defined as “a cost management tool for reducing the overall cost of a product over its entire life-cycle with the help of production, engineering, research and design”.

Several authors, in fact, assume that target costing is applicable only early in the product life cycle (i.e., during product specification and design). Additionally, should-cost analysis allows for geographical cost comparisons and fosters cooperative supplier relationships by reducing knowledge gaps and encouraging cost-saving measures. Continuous monitoring ensures that procurement teams stay informed and maintain optimal cost levels, leading to long-term savings and competitive pricing.

Company X, a well-known automotive manufacturer, faced fierce competition and needed to cut production costs while maintaining quality. By conducting extensive market research, they identified customer needs and preferences, which guided the elimination of non-essential features. The company set a target cost aligned with these customer expectations and collaborated with suppliers to optimize material costs. As a result, significant cost reductions were achieved while maintaining product quality and competitiveness, leading to increased market share and higher profitability. Regular cost monitoring throughout the development cycle is essential to stay within the target cost. This involves proactive cost planning and being flexible in design to mitigate risks such as market changes, regulatory requirements, and supply chain disruptions.